Beneath the roar of machinery and the rhythm of the assembly line lies a component fundamental to the very movement of modern industry: Industrial Wire Rope. Far more than a simple cable, it is the resilient tendon that transmits power, the reliable artery of material flow, and the silent backbone supporting the immense weights and critical processes of manufacturing. From the towering cranes of shipyards to the precise conveyance systems of automotive plants, wire rope enables the lifting, pulling, and structural support that define contemporary production. Its unparalleled combination of strength, durability, and flexibility makes it an indispensable, though often overlooked, engineering asset. This comprehensive guide delves into the anatomy, applications, and critical advantages of Industrial Wire Rope, providing the essential knowledge for selecting, maintaining, and leveraging this vital technology to ensure maximum operational safety, efficiency, and return on investment.

I. Introduction: The Backbone of Modern Manufacturing

In the grand picture of contemporary industrial civilization, countless visible robotic arms, roaring production lines, and towering steel structures form the manufacturing scene we know. However, behind these behemoths, there is a component that, while not always conspicuous, is absolutely vital. It acts like resilient tendons and nerves, transmitting power and motion to every corner. This is the Industrial Wire Rope. It is far from a simple metal cable; it is an engineered artifact, meticulously designed and rigorously manufactured, serving as the silent backbone supporting the efficient and safe operation of modern manufacturing.

An Industrial Wire Rope is essentially a flexible load-bearing component made by first twisting multiple wires into strands, and then twisting multiple strands around a core. This multi-layered structure gives it unparalleled strength, toughness, and adaptability. Its core mission can be summarized into three functions: Lifting – hoisting hundreds or even thousands of tons of raw materials, semi-finished products, or giant machinery into position; Pulling/Traction – precisely pulling and positioning workpieces on automated production lines; Structural Support – acting as tension members to provide a stable framework for large structures or equipment. Whether on the gantry cranes of busy ports, the overhead assembly lines of automotive plants, or beside the hot rolling mills of steel mills, the presence of Industrial Wire Rope is ubiquitous. It is the artery of material flow and the pulse of the production rhythm.

Its indispensable status stems from three core traits: exceptional strength, enabling it to withstand extreme loads without breaking; outstanding durability, allowing it to resist long-term wear, fatigue, and harsh environments; and crucially, reliability, providing a safety barrier for high-risk industrial operations. Failure at any point can trigger a chain reaction, leading to production stoppages, equipment damage, and even personnel casualties, the cost of which is immeasurable. Therefore, understanding, selecting, and maintaining Industrial Wire Rope has become a fundamental and critical task in the operational management of manufacturing enterprises.

From a macro industrial perspective, almost all heavy and high-end manufacturing industries deeply rely on Industrial Wire Rope. In automotive manufacturing, it is essential from sheet metal handling in stamping shops to engine hoisting in assembly lines. In shipbuilding, the heavy gantry cranes used for block assembly rely on giant wire ropes at the core of their lifting gear. In the steel and metallurgy industry, the opening of furnace lids, handling of continuous casting blooms, and lifting of hot-rolled coils are all performed under the traction of wire ropes. Even in the production and installation of wind power equipment, the lifting of large components depends on their strong load-bearing capacity. It can be said that without Industrial Wire Rope, the scale, automation, and efficiency of modern manufacturing would be unattainable.

II. Understanding Industrial Wire Rope: Composition and Design

Different keys open different locks. For Industrial Wire Rope tasked with heavy duties in harsh environments, its performance and service life are fundamentally determined by its intrinsic composition and ingenious design. It is not a homogeneous steel bar but a complex mechanical system where every detail—from the material of a single wire to the lay direction of the final rope—is precisely calculated, collectively defining its performance in specific manufacturing operations.

Let’s first deconstruct a standard Industrial Wire Rope. It typically consists of three basic elements: wires, strands, and a core.

* Wires: These are the fundamental building blocks. Their material directly determines the basic characteristics of the wire rope. The most common is high-strength carbon steel, which achieves very high tensile strength through cold drawing processes. For environments requiring corrosion resistance, such as marine operations or chemical plants, stainless steel wires are used. For general outdoor environments or slightly corrosive conditions, galvanized steel wires offer a good balance between cost and rust resistance. The strength, toughness, and surface treatment of the wires themselves are the foundation of the rope’s performance.

* Strands: Multiple wires are twisted together in a specific geometric arrangement to form a “strand.” The construction of the strand (e.g., number of wires, arrangement layers, lay length) directly affects the rope’s flexibility and abrasion resistance. For instance, a strand made of numerous fine wires will be very flexible, suitable for running over small-diameter sheaves; while a strand made of fewer, thicker wires will be stiffer and more wear-resistant.

* Core: This is the foundational support for the strands and profoundly impacts the structural integrity and performance of the entire wire rope. Cores are mainly divided into two categories: Fiber Core (FC) and Steel Core (SC). Fiber cores, usually made of natural or synthetic fibers, can store ample lubricant, providing continuous lubrication for the internal wires while giving the rope high flexibility and good resistance to shock loads. Steel cores, which can be an independent wire strand (IWSC) or an independent wire rope (IWRC), provide higher crushing strength, better structural stability, and higher heat resistance, but with reduced flexibility.

Understanding the basic composition, let’s look at its “recipe”—the rope’s construction. Common designations like “6×19”, “6×37”, or “7×7” are not random numbers; they precisely describe the rope’s construction. The first number indicates the number of strands in the rope, and the second number represents the approximate number of wires per strand. For example, “6×19” means the rope consists of 6 strands, each with approximately 19 wires. Generally, for the same diameter, more strands with finer wires result in a more flexible rope; conversely, fewer strands with thicker wires make it more abrasion-resistant. Therefore, when selecting a wire rope for a crane in manufacturing operations, a more flexible 6×37 construction might be preferred if it needs to frequently pass over sheaves; whereas for fixed guy lines mainly under tensile load, a more wear-resistant 6×19 construction might be more economical and durable.

Furthermore, the Lay—the relationship between the direction the strands are twisted into the rope and the direction the wires are twisted into the strands—is crucial. There are two main types: Regular Lay and Lang Lay. In Regular Lay, the rope lay direction is opposite to the strand lay direction. This design reduces the rope’s tendency to spin under load, making operation more stable, and is the absolute mainstream for hoisting applications. Lang Lay, while more flexible and wear-resistant, is prone to rotation and is used only in specific situations.

Finally, Coating and Lubrication are the invisible guardians that extend the life of Industrial Wire Rope. Before leaving the factory, the rope is impregnated with specialized lubricating grease. This lubricant not only reduces friction between internal wires, thereby significantly delaying fatigue failure, but also forms a protective film on the wire surfaces to resist moisture and corrosive agents. In some special applications, a polymer coating, such as PVC or nylon, may be applied externally to the rope for additional mechanical protection and corrosion resistance.

A clear diagram of a wire rope cross-section can intuitively display its complex internal world: the central core tightly surrounded by multiple strands, with each strand itself composed of dozens of fine wires arranged precisely. This multi-layered structure is the secret to combining high strength, flexibility, and durability.

III. Key Applications of Industrial Wire Rope in Manufacturing Operations

In the veins of modern factories, Industrial Wire Rope acts like resilient tendons and ligaments, converting power into precise motion and connecting scattered workstations into efficient assembly lines. Its applications are so widespread that they permeate almost every process requiring lifting, moving, pulling, or securing. In these scenarios, its reliability and safety are not just matters of efficiency but lifelines for production safety.

1. Material Handling and Lifting Equipment: The Symbol of Strength

This is the most classic and demanding field for Industrial Wire Rope. In the logistical heart of manufacturing—warehouses and transfer areas—giant equipment like overhead cranes, gantry cranes, and jib cranes stand tall, and their power transmission ultimately relies on the Industrial Wire Rope wound on drums and sheave blocks.

* Scenario Description: Imagine a steel fabrication plant where a hot steel billet is pushed out of a furnace and needs to be accurately fed into a rolling mill. A heavy-duty overhead crane’s hook suspends a specialized C-hook, connected to the hoisting mechanism by a thick, robust Industrial Wire Rope. It must not only bear the tens of tons of the billet’s weight but also endure high-temperature radiation and potential metal dust in the workshop. Every smooth lift and traverse is a severe test of the rope’s strength, heat resistance, and fatigue performance. Any oversight or improper selection could lead to catastrophic consequences. Similarly, in a heavy machinery manufacturing plant, the wire ropes used in the gantry cranes for assembling large excavators or port machinery need extremely long service life and stable elongation characteristics to ensure positioning accuracy and safety under long-term, frequent use.

2. Assembly and Conveyance Systems: The Pulse of Rhythm

The soul of modern manufacturing lies in automation and continuous flow production. Here, Industrial Wire Rope transforms into a precise transmission medium, driving vast conveyance systems.

* Scenario Description: In the final assembly line of automobile manufacturing, car bodies move between workstations via overhead conveyor chains. Many advanced conveyance systems use “Power & Free” technology, the core of which is trolleys pulled by Industrial Wire Rope. The rope circulates under traction from drive stations, propelling the body-carrying carriers forward, stopping, lifting, and lowering. This requires the rope to have not only sufficient strength but also excellent flexibility and resistance to bending fatigue to cope with the continuous bending and straightening over countless guide wheels. Additionally, its surface often requires a clean coating or material to avoid contaminating the precision body below. In this application, the smooth and reliable operation of the wire rope directly determines the pace and efficiency of the entire production line.

3. Structural Support and Rigging: The Invisible Skeleton

Beyond dynamic handling, Industrial Wire Rope also shines in static or semi-static support and fixing roles, acting as an “invisible skeleton.”

* Scenario Description: During the construction of large industrial buildings, Industrial Wire Rope is often used as stay ropes to provide lateral support for tall steel structures (like building columns, chimneys), enhancing their stability. In equipment installation, Rigging operations are crucial—before large reactors, generator rotors, or wind turbine nacelles are positioned, complex securing and hoisting are performed using wire rope slings and lashings. These tasks require wire ropes with a very high safety factor and good handling characteristics for workers to easily secure and hook. Here, the rope’s construction (e.g., whether it’s non-rotating) and end terminations (e.g., whether it has swaged fittings) must be carefully selected based on the specific task.

4. Maintenance and Repair Operations: The Guarantee of Safety

When core equipment on the production line requires maintenance, Industrial Wire Rope becomes the key tool ensuring the safety of repair work.

* Scenario Description: When a die in a large stamping press needs replacement, the maintenance team uses a workshop hoist or temporarily hung slings to slowly lift the multi-ton die. The wire ropes used for this purpose, while perhaps not as thick as those on primary lifting equipment, demand equally high reliability. They must withstand potential shock loads and be easy to coil, store, and inspect. Regular, targeted inspections and correct storage are prerequisites for ensuring these “reserve forces” are ready when needed.

From the macro flow of materials to the micro positioning at workstations, from dynamic powerful traction to static stable support, the panoramic view of Industrial Wire Rope applications clearly demonstrates its irreplaceable core value in manufacturing operations.

IV. Analysis of the Core Advantages of Industrial Wire Rope in Manufacturing

In the battlefield of manufacturing, which seeks the ultimate balance between efficiency, cost, and safety, the choice of every component and process is crucial. In the core power and load-bearing sectors, the reason Industrial Wire Rope remains an enduring solution for over a century stems from a series of exceptional performance advantages that are difficult to replace.

1. Unmatched High Tensile Strength and Load-Bearing Capacity

This is the most fundamental advantage of Industrial Wire Rope. By twisting numerous high-strength wires into strands and then strands into a rope, it achieves a perfect combination of strength and toughness. Its breaking force can reach astonishing levels, easily handling the lifting demands of weights ranging from several tons to hundreds of tons common in manufacturing. Compared to solid metal components, the multi-wire structure disperses stress more effectively, avoiding brittle fracture. For instance, hoisting a multi-ton excavator boom in a heavy equipment manufacturing shop places absolute demands on the strength of the load-bearing component; any suspected weak point is unacceptable. Industrial Wire Rope, with its reliable material science and structural mechanics design, provides this “absolute power” concerning life and property safety.

2. Excellent Abrasion Resistance and Long Service Life

Manufacturing environments are often filled with metal dust, abrasive particles, and equipment requires frequent starts, stops, and travel over sheaves. Industrial Wire Rope, especially those treated with special processes and using coarse-wire outer strands, extremely strong abrasion resistance. Even if individual surface wires wear out over long-term use, the multi-redundant design ensures the overall strength does not collapse instantly, providing a valuable safety window for daily inspection and preventive replacement. In contrast, synthetic fiber slings often perform poorly against sharp edges and in abrasion resistance, while chains experience rapid strength loss after wear at the link contacts, which is hard to detect. The durability of Industrial Wire Rope directly translates into longer replacement cycles and lower cost-per-use, which is significant for manufacturing enterprises pursuing long-term stable operation.

3. Outstanding Flexibility and Fatigue Resistance

A common misconception is that wire rope is “stiff.” In fact, properly designed Industrial Wire Rope possesses excellent flexibility, allowing it to bend repeatedly over sheaves of a certain diameter without failing. This ability to withstand repeated bending, i.e., resistance to bending fatigue, is key to its widespread use in cranes, winches, and automated conveyance lines. Different choices like fiber core (FC) or independent wire rope core (IWRC) can tailor for different flexibility needs. This flexibility allows it to be wound onto compact drums, enabling long-distance power transmission and precise spatial positioning, which rigid linkage mechanisms cannot match.

4. Inherent Safety and Reliability

Safety is the insurmountable red line in manufacturing. The safety of Industrial Wire Rope is reflected at multiple levels. First, its failure mode is usually progressive, not instantaneous. From the breakage of individual wires, to an increase in localized broken wires, to final overall failure, there is a relatively obvious warning process, allowing for periodic inspection and warning. Second, it lacks the hidden risks of sudden chain breakage or failure due to coupler malfunction. Furthermore, high-quality wire ropes are manufactured in strict compliance with international standards, with clearly defined parameters like breaking force and working load limit, providing reliable basis for engineers to design safety factors. This predictable, manageable characteristic makes it one of the most trusted mediums for high-risk lifting operations.

5. Excellent Environmental Adaptability and Cost-Effectiveness

Whether facing high-temperature radiation in steel mills, sun and rain in outdoor yards, or corrosive atmospheres in chemical areas, Industrial Wire Rope can be adapted through different materials and protective processes. Zinc plating provides excellent rust protection; stainless steel resists various chemical media; special lubricants and coatings can withstand high temperatures. This broad environmental adaptability allows it to be embedded in almost any manufacturing operation scenario.

From a total cost of ownership perspective, Industrial Wire Rope demonstrates high cost-effectiveness. Although its initial purchase cost might be higher than some alternatives, its long service life, minimal maintenance requirements (only periodic lubrication), and the resulting high safety and low downtime risk collectively justify its position as the “optimal cost solution.”

V. How to Select the Most Suitable Industrial Wire Rope for Your Manufacturing Application

Selecting a wire rope is not simply “procuring by tonnage.” It is more like a precise “diagnosis and prescription,” requiring a comprehensive diagnosis of the “condition”—the specific application conditions—and then matching it with the most suitable “prescription”—the rope’s specifications and type. Incorrect selection will not only drastically shorten the rope’s life but also result in significant safety liabilities.Therefore, mastering a scientific selection methodology is an essential skill for every manager and engineer responsible for equipment and safety.

Step 1: Precisely Define Load Requirements

This is the cornerstone of selection. Two core parameters must be identified:

* Working Load: The maximum weight the rope needs to bear during normal operations. This includes the load itself, the rigging, and dynamic loads (e.g., inertia from starting and stopping).

* Safety Factor: This is the safety buffer set to account for unforeseen overloads, shock loads, and material performance variations. It is defined as the ratio of the rope’s minimum breaking force to the maximum working load. Different equipment types and operating modes have strict national or international standard requirements for safety factors (e.g., FEM, ISO). For instance, the safety factor for wire ropes on general factory overhead cranes is typically required to be 5 or higher. It is absolutely forbidden to select based solely on the breaking force being close to the working load; this is an extremely dangerous practice.

Step 2: Deeply Analyze Operating Environment and Conditions

The rope’s “living environment” directly determines its lifespan and performance. The following factors need careful assessment:

* Bending Fatigue: Will the rope frequently pass over sheaves or drums? What is the ratio of sheave diameter to rope diameter (D/d ratio)? A smaller ratio means higher bending stress. For high-frequency applications with small sheaves, a more flexible construction like 8×19 or higher strand count should be chosen.

* Abrasion Level: Is there friction against external structures (e.g., container edges, steel structures)? Are there abrasive particles (e.g., slag, sand)? In severely abrasive conditions, select a type with coarse outer wires and a tighter construction, like 6x19S (Seale) or 6x25F (Filler), trading some flexibility for longer wear life.

* Corrosion Risk: Is it in a dry, clean indoor workshop, or a humid, watery, or chemically corrosive (acid, alkali, salt spray) environment? For the latter, galvanized wire rope is mandatory. In industries with high cleanliness requirements (e.g., food, pharmaceuticals) or highly corrosive environments (e.g., offshore platforms, chemical plants), stainless steel wire rope should be considered.

* Temperature Impact: How high is the ambient temperature or the temperature of contacted materials? Standard fiber cores and lubricants have temperature limits (typically around 82°C / 180°F). Beyond this, wire ropes with special high-temperature lubricants or directly opting for steel core ropes are needed, the latter capable of withstanding temperatures up to 180°C / 356°F or higher (depending on specific material and construction).

Step 3: Weigh Performance Characteristics to Finalize Specifications

After clarifying the load and environment, trade-offs between key performance aspects must be made to finalize the specifications:

* Strength vs. Flexibility: This is a classic trade-off. For static or low-frequency lifting requiring high strength and abrasion resistance, a 6×19 class construction can be chosen. For high-frequency cycling requiring high flexibility and fatigue resistance, an 8×19 or 6×36 class construction should be selected.

* Core Type Selection: This is the key internal factor determining the rope’s “character.”

* Fiber Core (FC): Provides the best flexibility and elasticity, stores large amounts of lubricant, and has good shock load resistance. It is the ideal choice for most general-purpose hoisting applications.

* Independent Wire Rope Core (IWRC): Provides higher tensile strength, better crush resistance and high-temperature performance, excellent structural stability, and low rotation tendency. Suitable for severe conditions like multi-layer spooling, heavy loads, high temperatures, or external pressure.

* Surface Treatment and Lubrication: Based on the corrosion risk analyzed in Step 2, clearly choose Bright (uncoated), B Grade Galvanized (rust prevention for ordinary environments), or A Grade Galvanized (rust prevention for severe environments). Simultaneously, ensure the factory lubrication meets your operating temperature and requirements.

Selection Case Analysis:

* Scenario A: Overhead conveyor in an automotive assembly plant.

* Needs: Continuous operation, high bending frequency, requires smooth and quiet running, must avoid contaminating car bodies.

* Selection Advice: Highly flexible 8×19 class construction, fiber core, clean galvanized surface or polymer coating.

* Scenario B: Scrap handling magnet crane in a steel mill.

* Needs: Very heavy loads, significant shock loads, high ambient temperature, risk of abrasion and damage from sharp scrap.

* Selection Advice: High-strength 6x19S or 6x25FW construction, independent wire rope core for enhanced stability and heat resistance, A Grade galvanizing to resist high heat and humidity.

Professional selection requires deep expertise and practical experience. Communicating with suppliers with profound technical can help recommend the Industrial Wire Rope that achieves the best balance between strength, durability, flexibility, and cost for your application, ensuring maximum return on investment and safe, trouble-free operation.

VI. Ensuring Safety and Extending Life: Maintenance and Inspection Protocols for Industrial Wire Rope

The actual service life and safety of a well-designed and properly selected Industrial Wire Rope depend heavily on the maintenance and inspection it receives throughout its entire service life. Treating wire rope as an “install and forget” component is the biggest management mistake. A scientific and rigorous maintenance and inspection system is the critical bridge connecting its excellent inherent performance to long-term reliable service, and an important reflection of a company’s safety management culture.

Establish a Systematic Periodic Inspection Process

Inspection is the first and most important line of defense for identifying hidden dangers and preventing accidents. Inspections should be conducted at three levels:

* Daily Inspection: Performed by equipment operators before work or during shift changes. It involves a macroscopic observation of the visible parts of the rope to check for obvious damage, such as severe broken wires, crushing, kinks, abnormal deformation, or corrosion. This is the most basic safety check.

* Periodic Detailed Inspection: Conducted by trained dedicated maintenance personnel or managers according to a set schedule (e.g., weekly, monthly). The inspection needs to be systematic, thorough, and ideally performed with good lighting. The rope should be run slowly to allow all sections to be carefully observed and recorded.

* Special Inspection: Must be performed immediately after the rope experiences an abnormal event, such as overload, severe impact, or exposure to fire, to assess whether it can continue in service.

Master the Core Inspection Content and Discard Criteria

Inspection is not aimless looking but targeted “diagnosis.” Key inspection points and corresponding actions include:

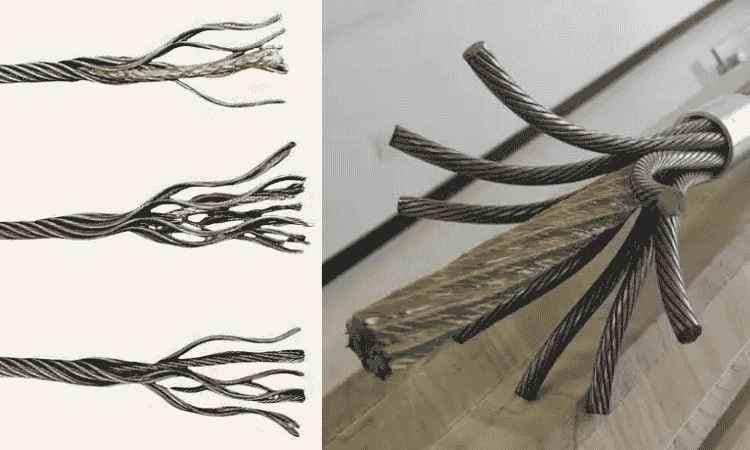

* Number and Distribution of Broken Wires: This is the most critical indicator. The total number of broken wires in one rope lay length needs to be counted. If the number reaches or exceeds the standard (e.g., for a 6×19 construction, regular lay rope, discard if 12 broken wires are found in one lay), the rope must be removed from service immediately. Furthermore, if breaks are concentrated in one area or occur predominantly in one strand, even if the total hasn’t reached the limit, it indicates severe local damage and warrants consideration for early removal.

* Abrasion and Diameter Reduction: Use calipers to periodically measure the rope diameter. When the diameter reduction due to wear reaches 7% or more of the nominal diameter, the rope’s strength has significantly decreased, and it should be discarded.

* Corrosion: Check if the wire surfaces have light rust or severe corrosion. Light rust can be mitigated by cleaning and lubrication. However, if corrosion has caused pitting on the wire surfaces, or internal lubrication has dried out and rust is present (evidenced by brown rust dust between strands), its strength and toughness are irreversibly compromised, and it must be discarded.

* Deformation and Damage:

* Kink: A permanent deformation in the rope caused by twisting. A kinked rope has its internal structure destroyed and must be removed from service immediately.

* Crushing: Local flattening of the rope diameter due to mechanical compression, severely weakening strength.

* Birdcaging: Severe distortion where strands and wires are forcibly displaced outward.

* Core Protrusion: Indicates severe wear of the outer strands.

* End Connection Condition: Check swaged fittings, spliced eyes, or wedge sockets for cracks, severe deformation, or signs of loosening.

Perform Scientific Lubrication and Cleaning

Lubrication is the “lifeblood” of Industrial Wire Rope. Its functions go far beyond reducing friction:

1. Prevents fretting wear and corrosion between internal wires.

2. Reduces friction between wires and sheaves/drums.

3. Provides corrosion protection for the core (especially fiber core).

A lubrication schedule should be established based on operating frequency and environmental conditions. Before lubrication, it’s best to remove accumulated dirt and old, contaminated grease using a stiff brush and solvent (like diesel fuel). After the solvent evaporates, apply Specialized Wire Rope Grease. Ensure the lubricant penetrates into the strand interstices.

Follow Correct Storage and Handling Practices

Even new wire rope can corrode if stored improperly (e.g., directly on damp ground). Unreel from the coil or wooden reel; avoid kinking. During operation, always ensure the rope spools evenly on the drum, avoid “birdcaging” and rope jumping; prevent the rope from jumping out of sheave grooves; eliminate practices like side pulling that generate abnormal stresses.

Establishing your own Standard Operating Procedures for wire rope inspection and maintenance is crucial. Through professional inspection training and standardized lubrication practices, the service life of wire rope can be greatly enhanced, providing a solid guarantee for production safety.

VII. Industry Standards and Safety Regulations for Industrial Wire Rope

In the globalized manufacturing system, standardization is the cornerstone for ensuring product reliability, interchangeability, and safety. For Industrial Wire Rope, which concerns life and property safety, adherence to strict international and national standards is not an option but a mandatory requirement. These standards provide authoritative technical basis for the design, manufacture, testing, selection, and discard of wire ropes, forming the core link in the safety management system.

Overview of Core International and National Standards

Globally, there are several widely recognized technical standard systems for wire ropes, the most important include:

* ISO 2408: Steel wire ropes — Requirements: A fundamental international standard specifying wire rope classification, materials, mechanical properties, dimensional tolerances, testing methods, and other important parameters. It provides a unified language for global trade and technical exchange.

* EN 12385: Steel wire ropes — Safety: A set of European standards with global influence. It provides detailed classification based on wire rope applications (e.g., cranes, lifts, aerial ropeways) and specifies safety requirements for factors like safety factors, proof loads, and use information.

* ASTM A1023/A1023M: A standard developed by ASTM International covering general requirements for various wire rope constructions.

In China, corresponding national standards like GB/T 20118 (Steel wire ropes for general purposes) and GB 8918 (Steel wire ropes for important purposes) align technically with international standards while also providing specific regulations for the domestic production and use environment. These standards collectively ensure that qualified wire rope products on the market have comparable and reliable basic performance indicators.

Core Meaning and Value of Standards

Deeply understanding the meaning of standards is crucial for the equipment management, procurement, and safety supervision departments of manufacturing enterprises. The value of standards is mainly reflected in:

* Performance Assurance: Standards define the nominal tensile strength grades of wire ropes (e.g., 1770 MPa, 1960 MPa) and specify their minimum breaking force requirements. This is the basis for selection calculations.

* Definition of Safety Factors: Standards provide recommended safety factor values for different equipment types and operating conditions. For instance, mobile cranes, due to their complex loadings, typically require higher safety factors than standard overhead cranes. Strict adherence to these factors is the primary measure to prevent accidents during the design phase.

* Quality and Consistency Control: Standards regulate wire chemical composition, rope diameter tolerance, lay quality, lubrication requirements, etc., ensuring standardized production and product consistency.

* Traceability: Compliant products must have clear identification, including construction, diameter, strength grade, governing standard, manufacturer’s mark, etc., and be accompanied by corresponding certificates of compliance. This establishes a chain of responsibility from production to use.

Compliance: Legal Obligation and Risk Management

In most countries and regions, using wire ropes that comply with specific standards on lifting equipment is a statutory safety requirement. Occupational health and safety regulations explicitly require employers to provide safe work equipment. Using unmarked, falsely marked, or non-compliant wire ropes not only risks penalties from regulatory bodies but also entails severe legal liability in case of accidents.

Therefore, integrating standards compliance into daily management processes is central to corporate risk management. This includes:

1. Procurement Stage: Clearly require products to comply with specified standards and provide type test certificates or certificates of compliance.

2. Acceptance Stage: Verify that physical markings match the certificates.

3. Use and Maintenance Stage: Develop internal safety operating procedures based on the inspection guidelines and discard criteria recommended in the standards.

In summary, the standards and regulations for Industrial Wire Rope are not constraints but wisdom crystallized through countless practical tests to ensure safety and efficiency. They are a technical language, a safety baseline, and the legal embodiment of a company fulfilling its social responsibilities. Deep understanding and strict implementation of these standards are essential paths to building a modern, responsible manufacturing industry.

VIII. How to Choose a Reliable Industrial Wire Rope Supplier

After deeply understanding the technical points and safety regulations of Industrial Wire Rope, how to choose a trustworthy supply partner becomes a key decision in ensuring this knowledge translates into actual operational safety and efficiency. This choice concerns not just the cost of a single transaction but long-term production stability, equipment safety, and total cost of ownership.

Assess the Supplier’s Technical Support Capability

A top-tier supplier’s value lies not only in providing products but also in providing solutions. Therefore, technical support capability is the primary evaluation dimension.

* Application Knowledge: Excellent suppliers should have a deep understanding of typical wire rope applications across major industrial sectors (e.g., ports, metallurgy, automotive manufacturing). They should be able to listen to your specific needs, including equipment type, operating frequency, environmental challenges, rather than just asking “how thick a rope do you need?”

* Selection Guidance: They should be able to provide professional selection advice based on your operating conditions, explaining the reasons for recommending specific constructions, core types, and materials, helping you find the optimal balance between strength, wear resistance, flexibility, and cost.

* Problem Diagnosis: When abnormal wear, broken wires, or other early failure signs appear, they should be able to send technical personnel or, based on photos and descriptions you provide, assist in analyzing the root cause—whether it’s improper selection, incorrect installation, inadequate maintenance, or operational error—and propose improvements.

Scrutinize the Product Quality Assurance System

Product quality is the foundation of safety. Quality assessment should focus on the system, not just individual products.

* Certifications and Standards: Confirm if the supplier’s production system is certified by quality management systems like ISO 9001. Whether their products explicitly comply with the aforementioned international or national standards (e.g., ISO 2408, EN 12385).

* Manufacturing Process and Testing: Understand if the supplier possesses advanced production equipment (e.g., tandem wire drawing machines, intelligent closing machines) and strict in-process quality control. Whether they conduct incoming raw material inspections and perform full-scale destructive tests like breaking force tests, torsion, and bending tests.

* Traceability: Ensure every wire rope has clear, permanent identification and corresponding test certificates, guaranteeing full traceability of the product.

Evaluate Comprehensive Service and Support

Reliable service minimizes the user’s lifecycle operating costs.

* Inventory and Delivery: Does the supplier maintain safety stock of common specifications to ensure fast delivery times, reducing production losses from waiting for spare parts?

* Technical Training: Can they provide professional training on wire rope knowledge, safety inspection, and discard standards for your equipment management, operation, and maintenance teams?

* Field Service: When needed, can they provide professional installation guidance, replacement services, or site surveys?

* After-sales Response: When technical inquiries or after-sales issues arise, is there a smooth channel and a professional team to provide timely and accurate responses?

Establish Long-Term Partnership Relations

Building a long-term cooperative relationship with a reliable supplier offers value far beyond the short-term price advantages of multi-sourcing. Long-term cooperation means the supplier gains a deeper understanding of your business and specific needs, can provide more proactive maintenance and replacement plans, and may even consider your personalized needs in product development. This strategic collaborative relationship transforms the supply chain into a stable “value chain,” jointly committed to improving overall equipment effectiveness and safety performance.

Therefore, the process of selecting an Industrial Wire Rope supplier is a systematic evaluation. It requires you to look beyond the single dimension of price and make a comprehensive assessment from multiple angles such as technical capability, quality system, service level, and long-term partnership potential, ultimately finding a strategic partner that can truly safeguard your safe production.

IX. Conclusion: Industrial Wire Rope – The Indispensable Lifeline of Modern Manufacturing

From roaring steel mills to precision automotive assembly lines, from ports lined with giant ships to towering wind power sites, Industrial Wire Rope supports the very heartbeat of modern manufacturing with its resilient stance, silently yet powerfully. Our journey of exploration began by deconstructing its intrinsic precision design, traversed its key roles in various manufacturing operations, analyzed its irreplaceable performance advantages, and finally settled on the practical wisdom of scientific selection, standardized maintenance, and regulatory compliance.

Reviewing the article, we can clearly see a logical thread: the value of Industrial Wire Rope stems from its engineering excellence, integrating materials science, structural mechanics, and manufacturing processes. This excellence translates into high strength, high durability, high flexibility, and high safety in practical applications, making it one of the most economical and reliable solutions for handling core manufacturing processes like heavy load handling, power transmission, and structural support.

However, we must deeply recognize that even the most excellent product is only one link in the entire safety chain. Whether its potential is fully realized and its inherent safety maintained depends greatly on the “human factor” behind it. This includes:

* Decision-makers’ Awareness: Do they view it as a critical safety component rather than a common consumable?

* Engineers’ Selection: Is a scientific and rigorous selection and matching process performed?

* Operators’ Practices: Are correct operating procedures followed?

* Maintainers’ Diligence: Are regular, meticulous inspections and maintenance carried out?

Elevating the management of Industrial Wire Rope from a simple “procurement-replacement” model to a comprehensive “technology-safety-asset” management system is a significant mark of a modern manufacturing enterprise enhancing its intrinsic competitiveness and fulfilling its social responsibilities. This means establishing standardized processes, training professional personnel, and selecting reliable supply chain partners capable of providing full technical support.

Looking ahead, as manufacturing evolves towards greater intelligence and sustainability, Industrial Wire Rope technology itself is also advancing—higher strength materials, smarter monitoring technologies, and more environmentally friendly processes will continue to emerge. But regardless of technological iteration, its fundamental status as the “lifeline” of manufacturing will not change, nor will the ultimate pursuit of safety, reliability, and efficiency.

In summary, Industrial Wire Rope is far more than a cold steel cable; it is a symbol of strength, safety, and efficiency, the vital link connecting static equipment to dynamic production processes. Giving it the attention it deserves and investing the necessary resources for its scientific management is undoubtedly one of the most valuable investments in production continuity, asset safety, and employee life safety. On this resilient “lifeline” hangs the steady progress of modern manufacturing, today and in the future.

You can feel free to contact SICH Manufacturer in China for purchasing wire ropes and get the Crane Wire Rope Catalog: Email: info@sichwirerope.com